New 400,000-square-foot expansion demonstrates commitment to area, adding 240 jobs

By Morf Morford

Tacoma Daily Index

If you know anything about Pacific Northwest history – and culture and the economy – you know that timber and construction has been the heart of our economy and identity for well over a century.

And if you travel to almost any other country in Europe or Asia for example, you will notice that for the vast majority of housing construction wood is barely used.

Wood for construction purposes has been available, affordable and near infinitely adaptable for most of us for a long time.

It is difficult even imagine anything taking its place.

And it is even more difficult to imagine that such a product would make itself at home here in the epicenter of timber production.

But yes, it has happened.

James Hardie’s siding has been around for 125 years. First developed in Australia and then around the world, with a facility outside of Tacoma since 1998, James Hardie is expanding their Tacoma site by adding 400,000 square feet to the production site and 240 local jobs.

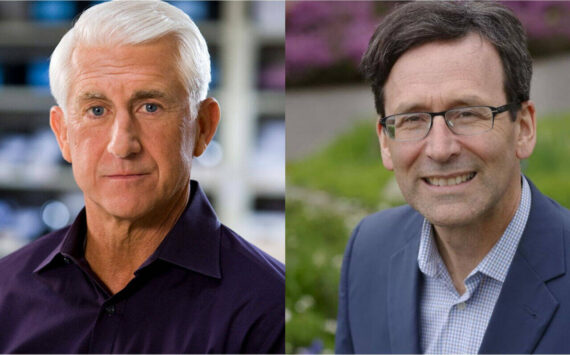

Pierce County Executive Bruce Dammeier, U.S. Congressional Representative Denny Heck,

Washington Governor Jay Inslee, James Hardie Industries Chief Compliance Officer and General Counsel Joe Blasko, President & CEO Economic Development Board Bruce Kendall, James Hardie Industries Tacoma Plant Assistant Manager Daniel Kronick. Photo courtesy of James Hardie

The $187 million expansion will increase James Hardie’s manufacturing capacity and capability in the Pacific Northwest to keep pace with continued growth. The 400,000-square-foot facility will help the company meet the demands of both today and the future through increased production and efficiency improvements.

The company, which is the No. 1 brand of siding in North America, also strives to contribute to the communities it calls home. Beyond purchasing over $30 million annually in local materials and services, James Hardie has supported local charities, such as the Tacoma Rescue Mission and Habitat for Humanity.

James Hardie developed fiber cement siding products in the early 1980s as a durable, low-maintenance alternative to wood and vinyl. James Hardie products combine innovation and versatility to offer a variety of design possibilities and is currently installed on more than eight million homes across North America.

The cellulose fibers used in HardiePlank are not derived from endangered species of wood. The cement and sand used is widely available from local sources. No toxic materials are used in the production of fiber-cement siding.

If you are not familiar with their siding, it looks similar to wood, is fire resistant, won’t curl or rot as wood might and adheres to paint better than wood siding. And common wood-consuming insects – like Carpenter ants and termites don’t like it.

James Hardie warrants the material for 50 years. But HardiePlank can last longer than that if painted and properly maintained.

HardiePlank comes in long, standard lap-siding lengths. HardiePanel, also composed of fiber-cement, is the tall, vertical panel version of HardiePlank, at 48 inches wide by 96 inches to 120 inches long.

Once you see it you will recognize it on all kinds of homes – even in the Pacific Northwest.